News information

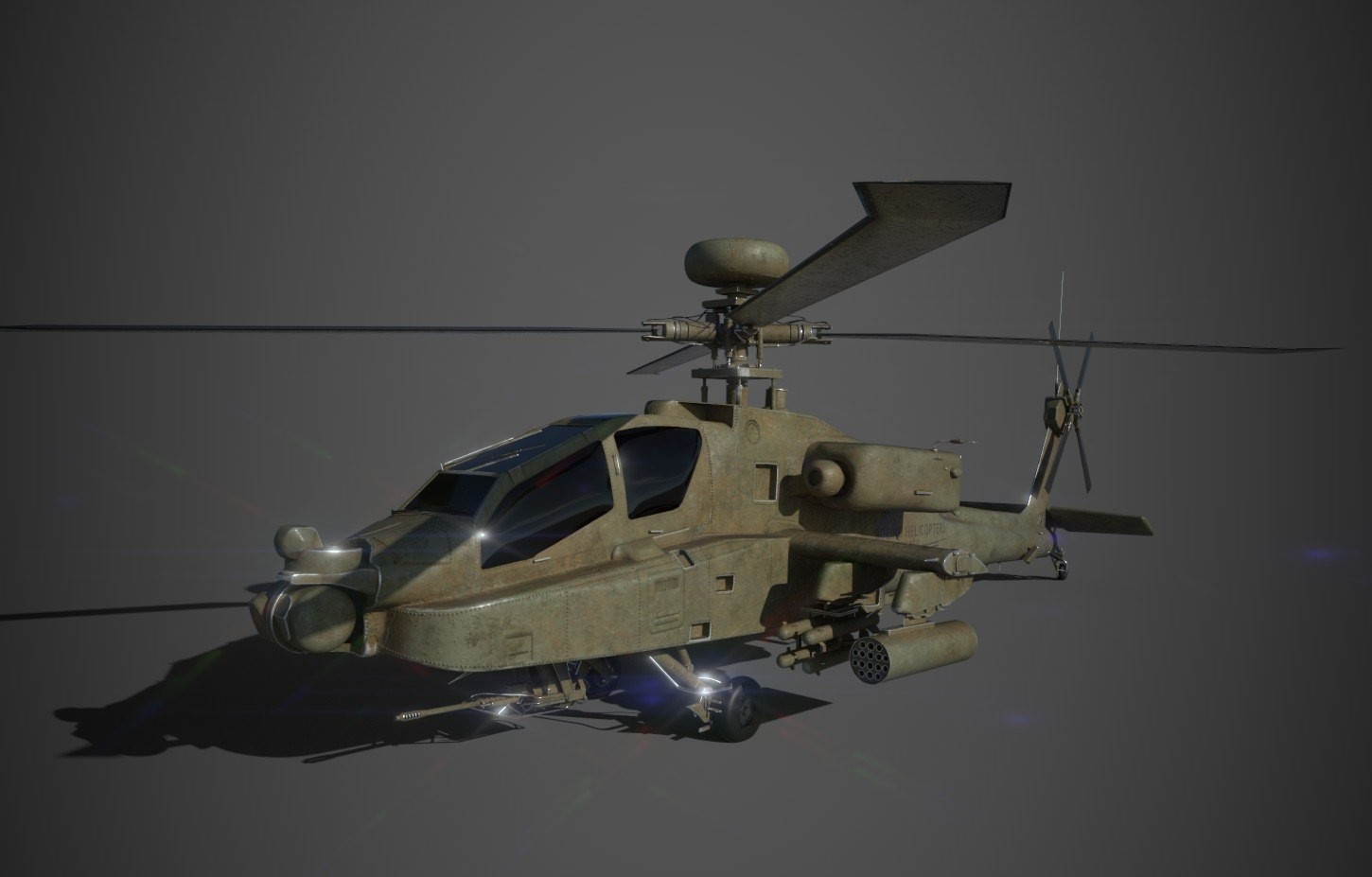

Professional model design and production, 1:1 realistic presentation, 19 years of focus on high simulation military models

What are the fighter model materials

Time:

2023-07-29

The choice of aircraft mold material often depends on factors such as the material, size and accuracy of the aircraft model to be manufactured, as well as a combination of factors such as manufacturing costs and service life. Common aircraft mold materials are as follows:

The choice of aircraft mold material often depends on factors such as the material, size and accuracy of the aircraft model to be manufactured, as well as a combination of factors such as manufacturing costs and service life. Common aircraft mold materials are as follows:

1. Steel mold: Steel mold is a commonly used mold material, which has the advantages of high hardness, good wear resistance, good heat resistance, etc., and is suitable for manufacturing large-size aircraft models.

2. Aluminum alloy mold: Aluminum alloy mold has the advantages of light weight, easy processing, good corrosion resistance, good heat dissipation, etc., which is suitable for manufacturing small-size aircraft models.

3. Resin mold: Resin mold is a new type of mold material, which has the characteristics of low cost, easy processing, light weight, etc., and is suitable for manufacturing small to medium-sized aircraft models. In addition to the above materials, there are some other materials can also be used as aircraft mold materials, such as carbon fiber, ceramics and so on. Different materials are suitable for different manufacturing requirements, and selecting the right material can greatly improve manufacturing efficiency and die life.

Prev: What are the acceptance criteria for the model?

Next: None

RELATED NEWS